Abstract - Raul Fangueiro and Martin Tamke

Bespoke Materials for Bespoke Textile Architecture

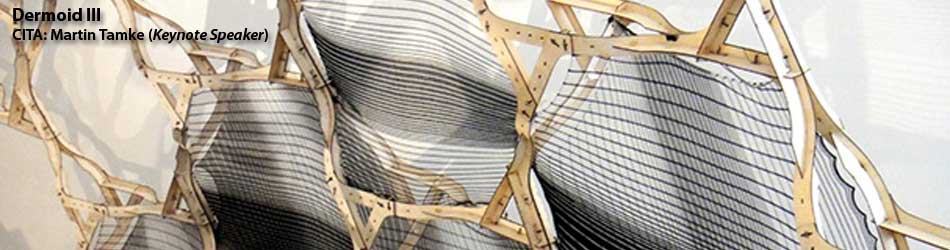

Scientific and technological advancements in the area of fibrous and textile materials have greatly enhanced their application potential in industrial sectors including architecture and engineering. Excellent performance accompanied by light-weight, mechanical flexibility, design flexibility, easy fabrication, relatively lower cost and tailor-ability due to the exclusive use of CNC machinery are the driving forces towards wide applications of highly bespoke textiles.

This digital framework creates a natural link to the field of computational design in engineering and architecture, where the concept of the digital chain, which integrates computational design, simulation and fabrication into, has been a major driver in the field. The extension of these concepts into the realm of textile fabrication opens up a potential to produce textiles highly bespoke to the forces and local areas of application in building structures.

The keynote will discuss the possible areas of application and benefits through a case study of a 9m high tower made from custom CNC made high tenacity knit. This was developed in a collaboration of textile engineers, architects, engineers with background in structural design and simulation and material testing, who came together in the COST action Novel Structural Skins. This is the point of departure to critically reflect the interdisciplinary efforts and processes, that need to be in place, when concepts of bespoke design and digital fabrication shall engage in the realm of textile materials.

[ presentation: PDF ] [ CITA's videos on vimeo ]